News

Thomas Uebelhart

Our new employee in production area

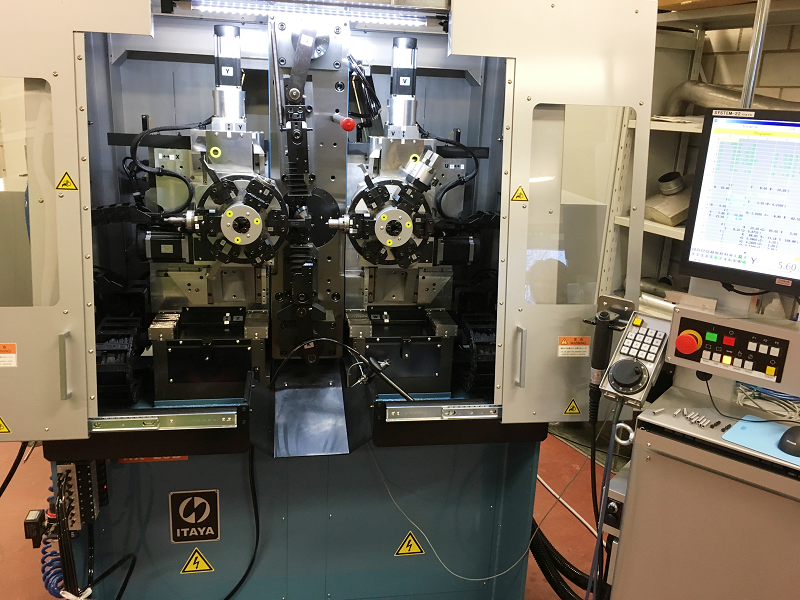

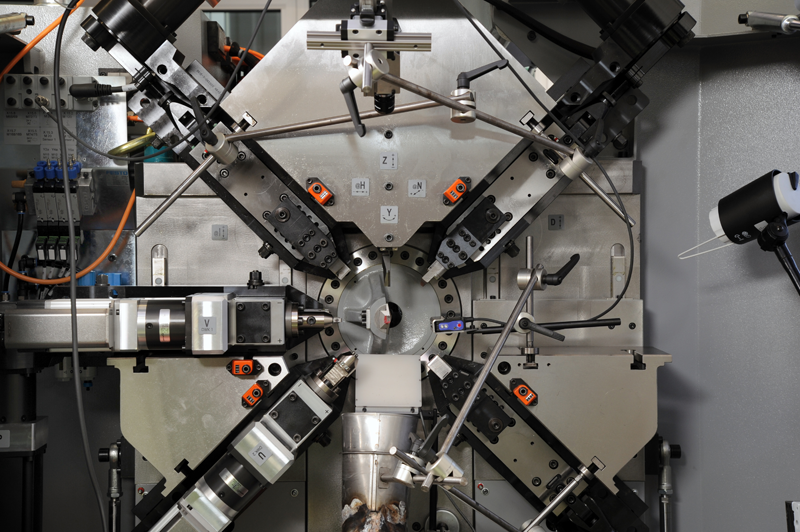

Itaya PC-8B

In March 2024, the new Itaya PC-8B CNC compression spring machine was successfully put into operation. This state-of-the-art machine offers a range of features that expand and enhance our production capabilities, including:

- Fully electronic control of 5 axes for precise and versatile machining capabilities.

- The wire diameter range is from Ø 0.1 to 0.8 mm.

- The maximum outer diameter is 25 mm.

- A visual length measuring system that ensures precise monitoring of the spring lengths during the production process.

- The machine is equipped with a pneumatic system for horizontal movement during cutting.

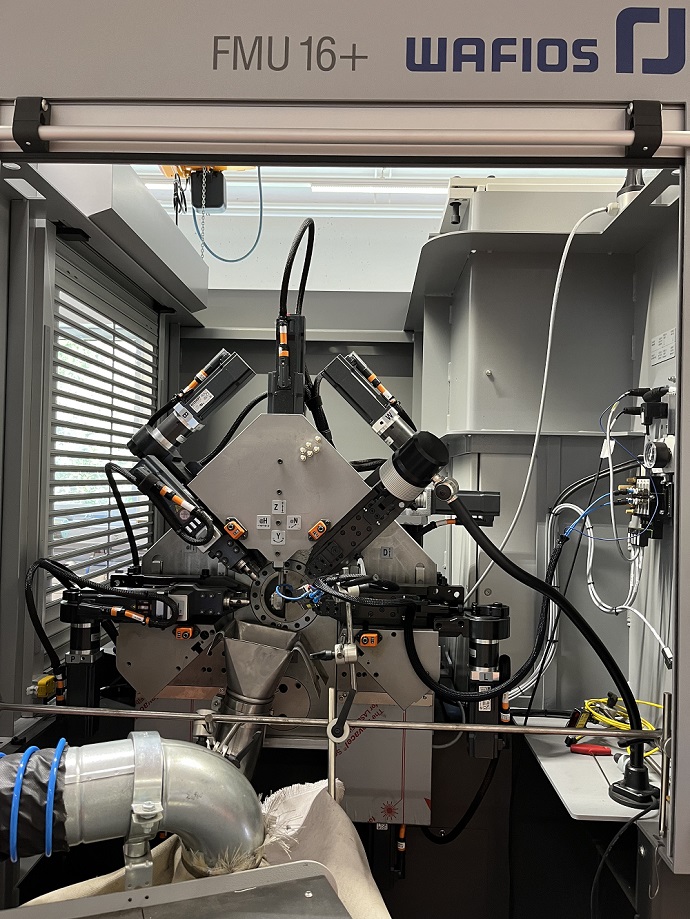

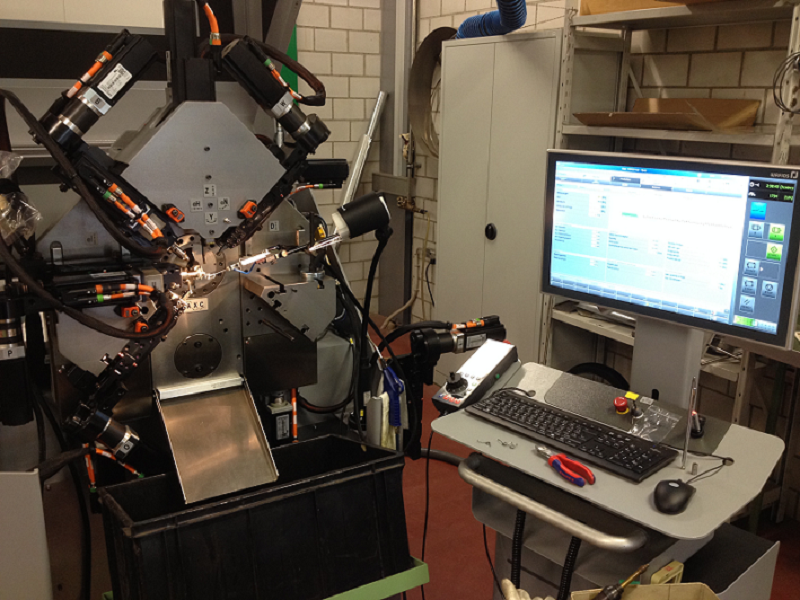

Wafios FMU-16

In November 2022, the new Wafios FMU-16+ CNC coiling, twisting and bending machine was put into operation. This machine offers:

- Full electronic control of up to 24 CNC axes

- Full-HD Multi-Touch monitor (min. 21.5")

- 8 programmable CNC axes

- Wire diameter range Ø 0.40 to 1.60 mm

- Wire infeed speed max. 140 m/min.

- High user-friendliness

MicroStudio PMZ-DC1-300

In February 2022, the new MicroStudio PMZ-DC1-300 load tester was put into operation. This automatic spring load tester is especially suitable for measuring in static and dynamic mode for lenght and force of tension- and compression springs. Technical details see below:

- Equipped with industrial PC in Windows 10 enterprise

- Sofware "Pminterface" and Pmar 8.1" for statistical analysis of the measurement results

- Equipped with 2 independent load cells (30 Newton and 300 Newton)

- Automatic compensation of the deformation of load cells

- Measuring range 0,2 - 300 Newton

- Load resolution 0,001 N and 0,01 N

- Max. spring outside diameter 38 mm

- Max. spring length 300 mm

Aaron Sperisen

Our new employee in production area

Nicole Häberli

Our new employee in administration area

Daniel Häberli

Our new employee in production and management

Dario Giombanco

Our new employee in logistics

Lucia Rocchetta

Our new employee in administration area

We wish Mrs. Rocchetta a lot of success in executing her new role and look forward to work with her.

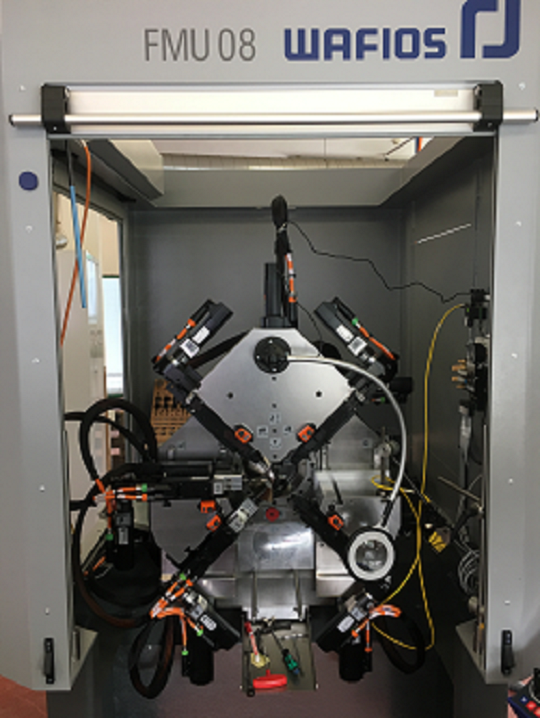

Wafios FMU-08

In February 2019, the new Wafios FMU-08 CNC coiling, twisting and bending machine was put into operation. This machine offers:

- Full electronic control of up to 20 CNC axes

- 8 programmable CNC axes

- Wire diameter range Ø 0.16 to 0.80 mm

- Wire infeed speed max. 120 m/min.

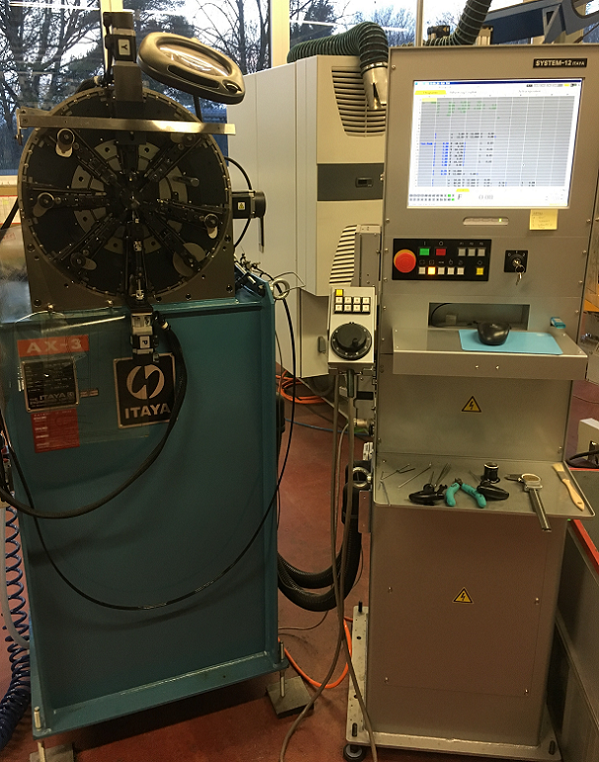

Itaya AX-3

In January 2018, the new Itaya AX-3 CNC coiling and bending machine was put into operation. This machine offers:

- Full electronic control of up to 9 CNC axes

- Wire diameter range Ø 0.05 to 0.30 mm

- Operational range of wire feed (axe F) 0 - 9999,98 mm

- AX-3 is qualified for tension springs as well

Itaya RX-20B

In December 2016, the new Itaya RX-20B CNC coiling, twisting and bending machine was put into operation. This machine offers:

- Full electronic control of up to 15 CNC axes

- Wire infeed speed max. 82 m/min.

- Wire diameter range Ø 0.50 to 2.00 mm

- Integrated camera measuring device including sorting chute

Wafios FMU-16

In September 2015, the new Wafios FMU-16 CNC coiling, twisting and bending machine was put into operation. This machine offers:

- Full electronic control of up to 24 CNC axes

- 11 programmable CNC axes

- Wire diameter range Ø 0.40 to 1.60 mm

- Wire infeed speed max. 120 m/min.

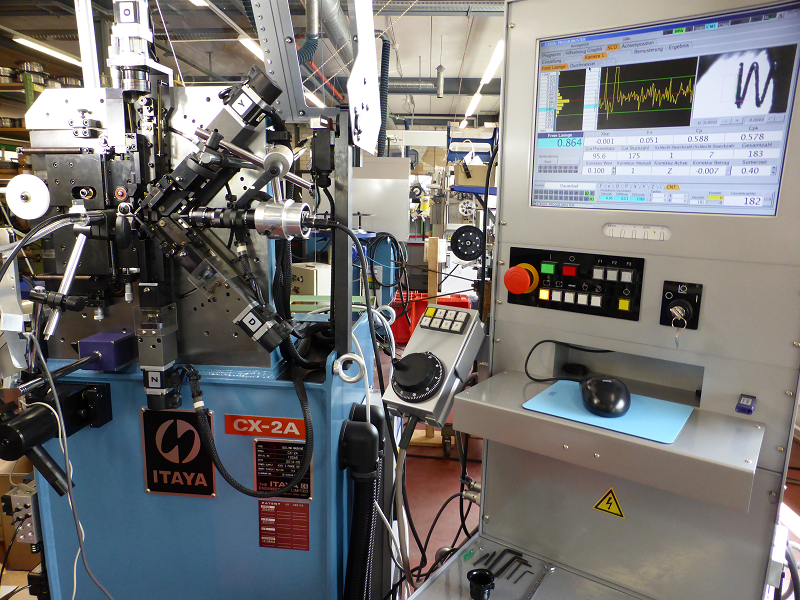

Itaya CX-2A

In September 2014, the new Itaya CX-2A CNC micro - compression spring machine was put into operation. This machine offers:

- Full electronic control of up to 8 CNC axes

- Wire diameter range Ø 0.03 to 0.20 mm

- Max. external spring diameter Ø 10 mm

- Wire infeed speed max. 122 m/min.

- Integrated digital video camera as a measuring device for spring length and diameter

Thomas Marrer

Our new employee in the production area

We wish Mr. Marrer a lot of success in executing his new role and look forward to work with him.

Wafios FMU-2.7

In March 2013, the new Wafios FMU-2.7 CNC coiling, twisting and bending machine was put into operation. This machine offers:

- Full electronic control of up to 24 CNC axes

- 11 programmable CNC axes

- Wire diameter range Ø 0.80 to 2.50 mm

- Wire infeed speed max. 120 m/min.

Kamatech G30

In October 2012, the new Kamatech G30 spring end grinding machine was put into service. This machine offers:

- Through-feed and down-feed grinding

- Wire diameter up to Ø 1.5 mm for through-feed grinding

- Wire diameter up to Ø 4.0 mm for down-feed grinding

- Max. spring length up to 250 mm

- Adjustable loading plate axis

- Loading plate up to 420 mm

Simplex MC 30

In April 2012, the new Simplex MC 30 CNC compression spring machine was put into operation. This machine offers:

- Full electronic control of up to 7 CNC axes

- Wire diameter range Ø 0.40 to 3.00 mm

- Max. external spring diameter Ø 60 mm

- Wire infeed speed max. 120 m/min.

- Integrated digital video camera as a measuring device for spring length and diameter

Wafios FMU-0.7

In June 2011, the new Wafios FMU-0.7 CNC coiling, twisting and bending machine was put into operation. This machine offers:

- Full electronic control of up to 24 CNC axes

- 11 programmable CNC axes

- Wire diameter range Ø 0.15 to 0.80 mm

- Wire infeed speed max. 120 m/min.

EN

EN  DE

DE  FR

FR